industrial bread making machine

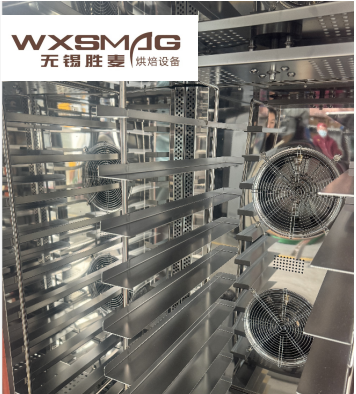

Industrial bread making machines represent the pinnacle of modern baking technology, offering comprehensive solutions for large-scale bread production. These sophisticated systems integrate multiple components including mixing units, dough processing sections, proofing chambers, and baking modules into a seamless production line. The machines feature advanced dough mixing technology that ensures consistent ingredient incorporation and optimal gluten development, while precision temperature controls maintain ideal conditions throughout the production process. Automated dough dividing and molding systems guarantee uniform product sizes and shapes, enhancing production efficiency and product consistency. Digital control panels provide operators with complete oversight of all processing parameters, from mixing speeds to baking temperatures and times. Most models can produce various bread types, from standard loaves to specialty items, with production capacities ranging from 500 to 5,000 loaves per hour. The machines incorporate safety features such as emergency stop buttons, overload protection, and automated cleaning systems. Modern industrial bread makers also feature energy-efficient designs, reducing operational costs while maintaining high output levels.